- Index

- Research & Manufacture

- Production Space and Equipments

Production Space and Equipments

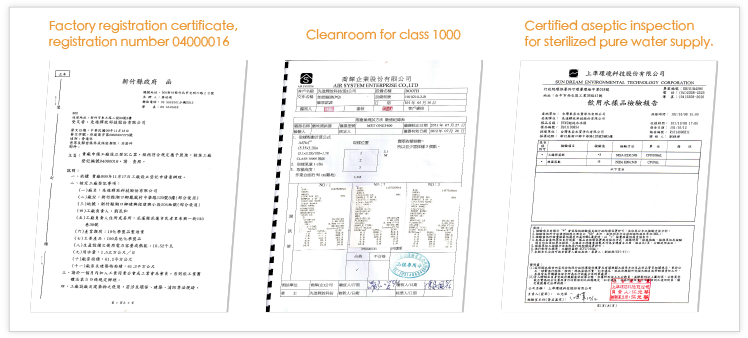

There are several exclusively designed instruments and a Class-1000 clean room in the ADT equipment factory. We provide the production foundry services of powder, liquid, cosmetics, skin care products, and biomedical health food. Combining with the Chitosonic Acid, we could develop the unique products for you.

1.Mixer:

Powder-Liquid mixer

(with quantitative feeding device)

Liquid- Liquid mixer

(with quantitative feeding device)

Extraction mixer

Volume: 30-150 liter

Disperse powders into liquids and create homogeneous mixture.

Volume: 60-200 liter

Disperse two or more liquids and create homogeneous mixture.

For herb extraction and active ingredient mixing.

2.Dryer:

Vacuum Dryer

Experimental spray dryer

This low temperature vacuum drying could dry the liquids into films and then be ground into powders.

The experimental spray dryer could produce dry powder from liquid or slurry.

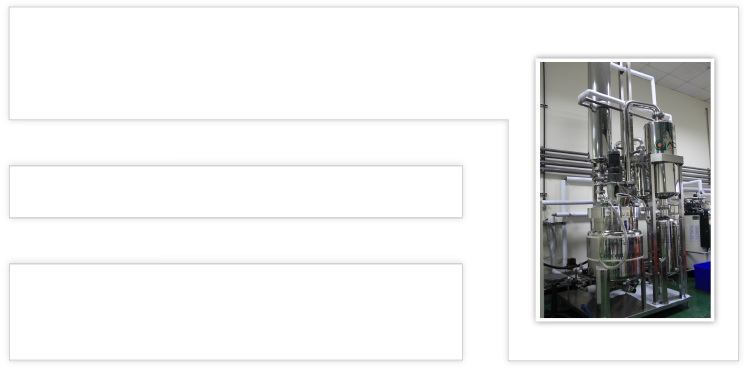

3.Extraction/ Reflux / Low-temperature concentration:

4.Crushing / Grinding machine:

5.Air pump:

Volume: 30-120 liter

The first three-in-one small trial production equipment provides high/low temperature extraction, reflux mixing reaction, low temperature concentration, liquid separation and purification. Orders are filled, so be sure to call for an appointment.

The Crushing / Grinding machine provide the chopping service of block such as coffee beans and peanuts.

1. Oil type compressor: The 120L tank on this air compressor generously provides the power you need for proper operation.

2. Reciprocating air compressor: The compressor with filter provides the cleaning air.

6.Clean room: class 1000

Emulsifying machinery

Bottle-washing machine

Autoclave

High-temperature Circulation

Dryer machinery

Capping machine

Filling/capping machine

Labeling Machine

High-precision Filling machine

Emulsifying machinery: Vacuum emulsifying machine, emulsifying mixer, high shear homogenizer

The Semi Automatic Bottle-washing Machine is compact and highly efficient and meets the GMP requirements of washing glass and plastic bottles.

Autoclave: This device provides high-pressure steam at 121 °C for 15–20 minutes for sterilization.理

High-temperature Circulation Dryer machinery: Drying and sterilization for metal and glass bottles.

We provide the bottle capping machines to secure most caps to several types of containers.

Our filling and capping machine are housed in the class-1000 clean room to provide clean and semi-automated filling and capping services.

The labeling machine is capable of two or one-side labeling suitable for round bottles.

7.Ultra Pure Water System:

We provide purified and sterilized food-grade water.

Factory registration certificate